Katana Steel

1. Types of Steel Used in Forging Katanas

Katanas can be forged using a variety of steel types, each contributing to the sword's overall characteristics such as blade sharpness, hardness, and flexibility.

1.1 Carbon Steel

High carbon steel, a subset of carbon steel, is frequently chosen for the construction of katanas. The rationale behind its widespread use is its unique combination of hardness and durability. The carbon content in this steel can vary, with different designations like 1045, 1060, or 1095, representing the carbon percentage.

- 1045 Carbon Steel: This is the lowest carbon steel used in katana making, making it relatively soft but also more resistant to shattering.

- 1060 Carbon Steel: A medium-carbon steel, 1060 offers a balance between hardness and durability.

- 1095 Carbon Steel: This high carbon steel yields exceptionally hard blades but is more prone to brittleness.

1.2 Spring Steel

Spring steels like 5160 and 9260 are recognized for their high resilience. They contain silicon, which increases their flexibility. These types of steel can endure greater stress compared to high carbon steel without becoming distorted, rendering them ideal for high-impact sword usage.

1.3 Stainless Steel

Characteristics of this steel makes it resistant to corrosion and rust. However, these type of steel tends to be less durable when subjected to impacts. Due to its fragility, it's generally deemed inappropriate for functional katanas. It's often used for decorative or ceremonial swords.

1.4 Powder Steel

Modern steel production technologies have led to the development of powder steel. This type of steel has a very homogeneous structure and allows for very sharp edges. It's often used in high-quality modern katanas.

Key Points:

- Carbon steel is the most common type of steel used in katana making, with varying carbon content that affects the blade's hardness and durability.

- Spring steel is valued for its resilience and is excellent for high-impact sword applications.

- Stainless steel, while more resistant to corrosion, is often only suitable for decorative or ceremonial swords.

- Powder steel, a product of modern technology, has a homogeneous structure that enables extremely sharp edges.

2. Katana Blade Construction Method

The type of steel used in a katana's construction is only half the story. Equally important is the way that steel is forged, treated, and crafted into a blade. Different construction methods contribute to a blade's durability, sharpness, and aesthetic appeal.

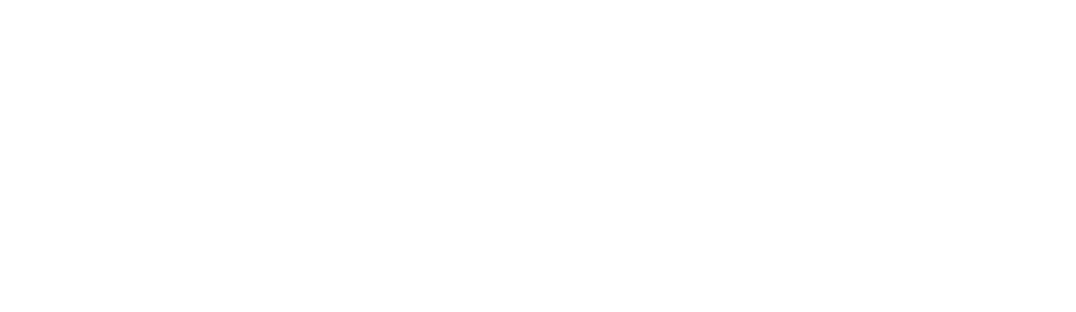

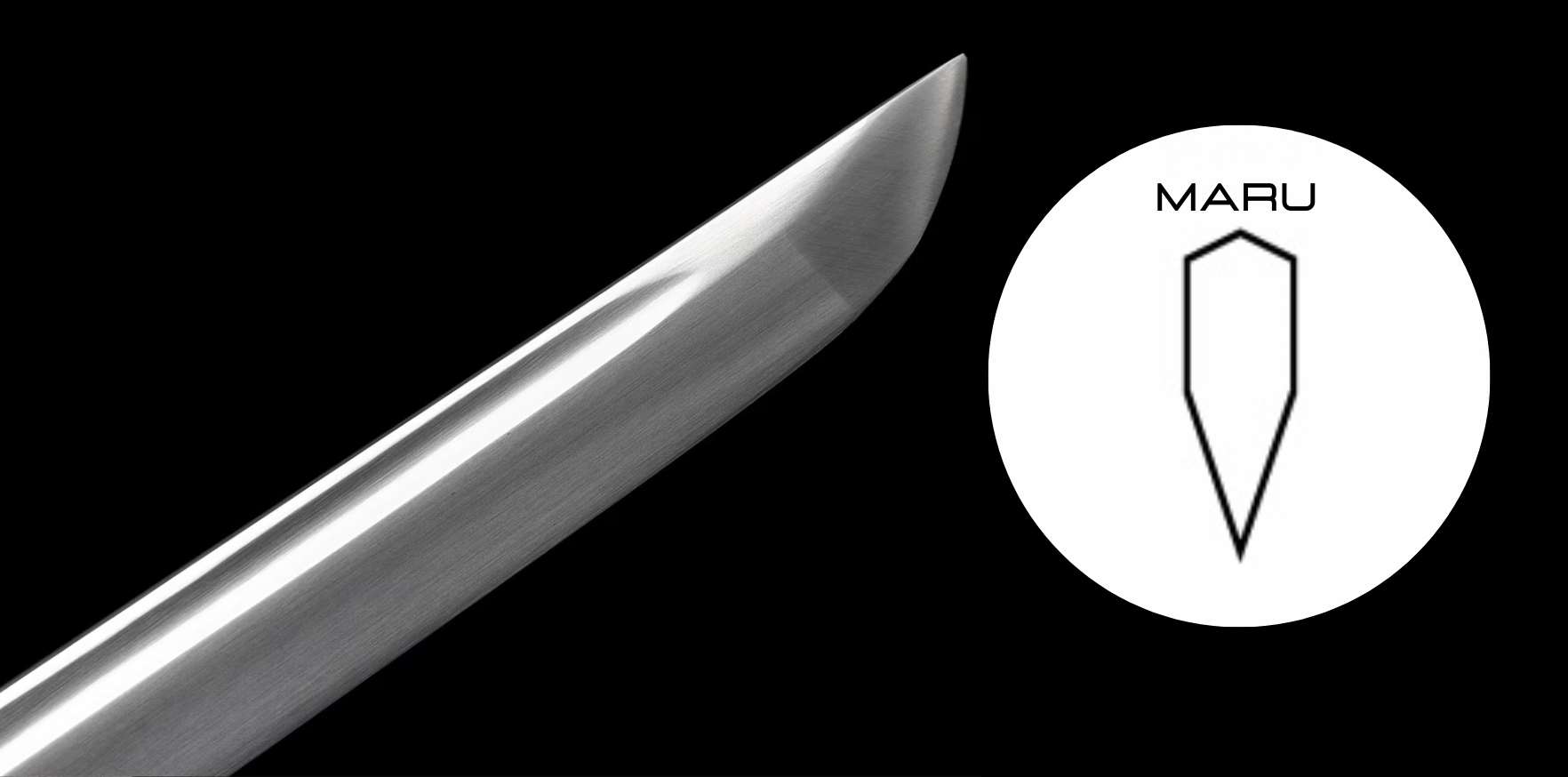

2.1 Maru Steel

Maru construction, also known as "through hardened" construction, involves the use of a single steel type. The entire sword is heated, then quenched and tempered to create a hardened blade. This method is typically used for economic swords, Iaito (practice swords), and Bokken (wooden swords).

2.2 Composite Steels

With the composite steel construction technique, the blade's edge is made from a harder steel, while a softer steel forms the spine. This approach harnesses the edge-holding capability of the hard steel and pairs it with the shock-absorbing qualities of the softer steel, effectively decreasing the chances of the blade snapping or fracturing.

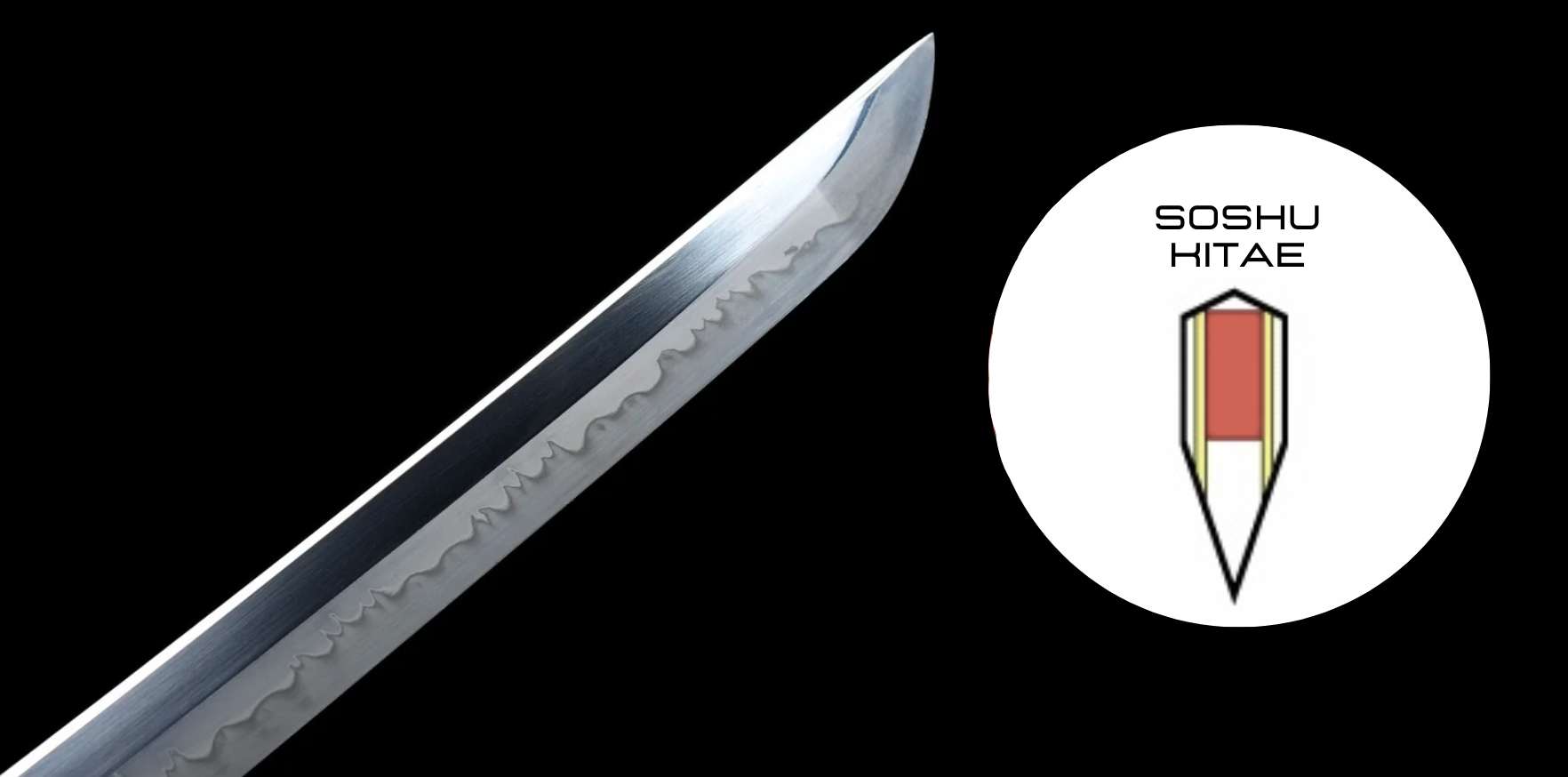

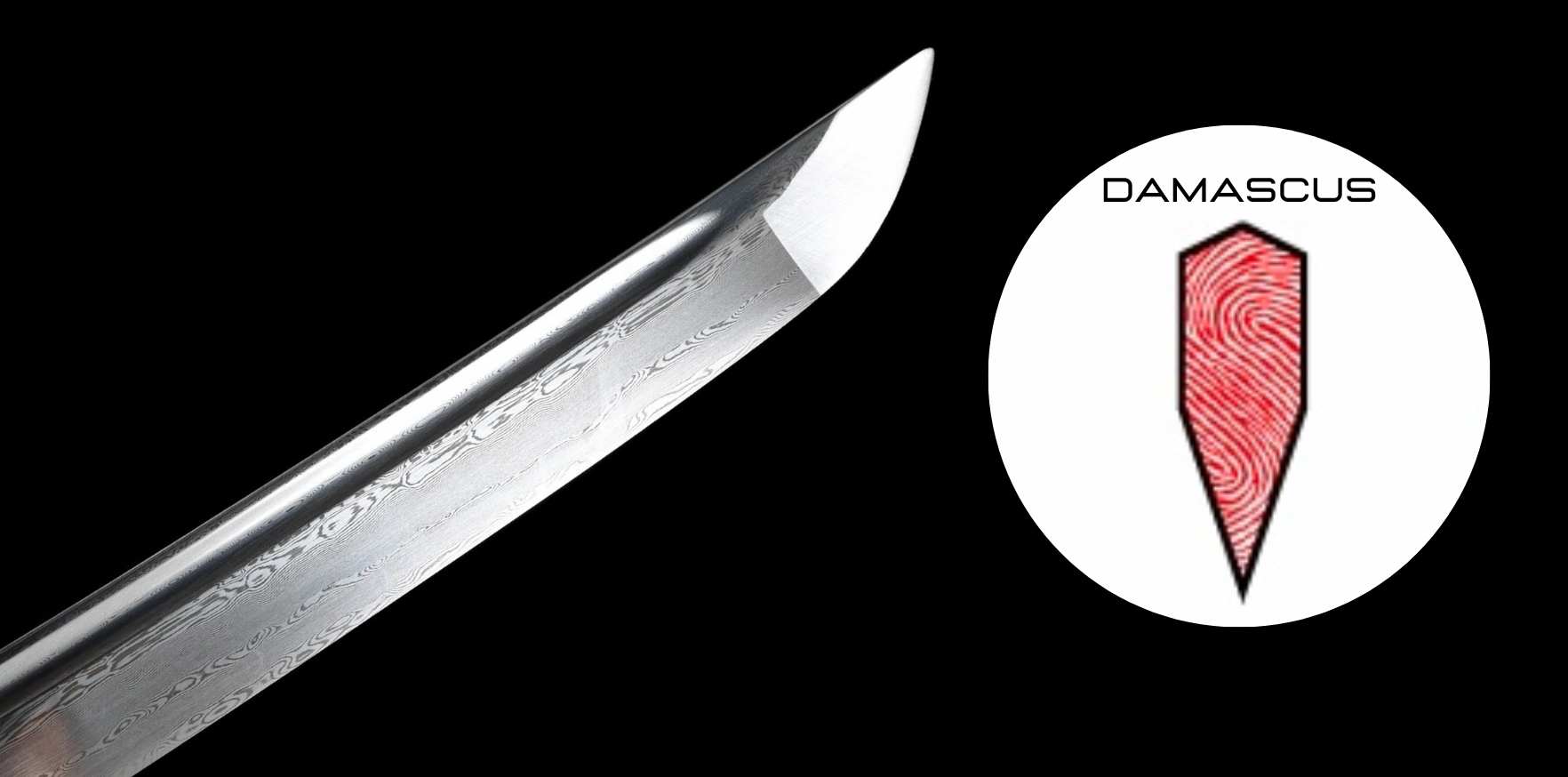

2.3 Laminated Steels

Laminated construction involves layering and folding multiple types of steel to create a katana blade. This method, which includes traditional Japanese steel folding, enhances the sword's visual appeal while also balancing hardness, toughness, and flexibility. The famous Hada (grain pattern) and Hamon (temper line) of traditional Nihonto are a result of this process.

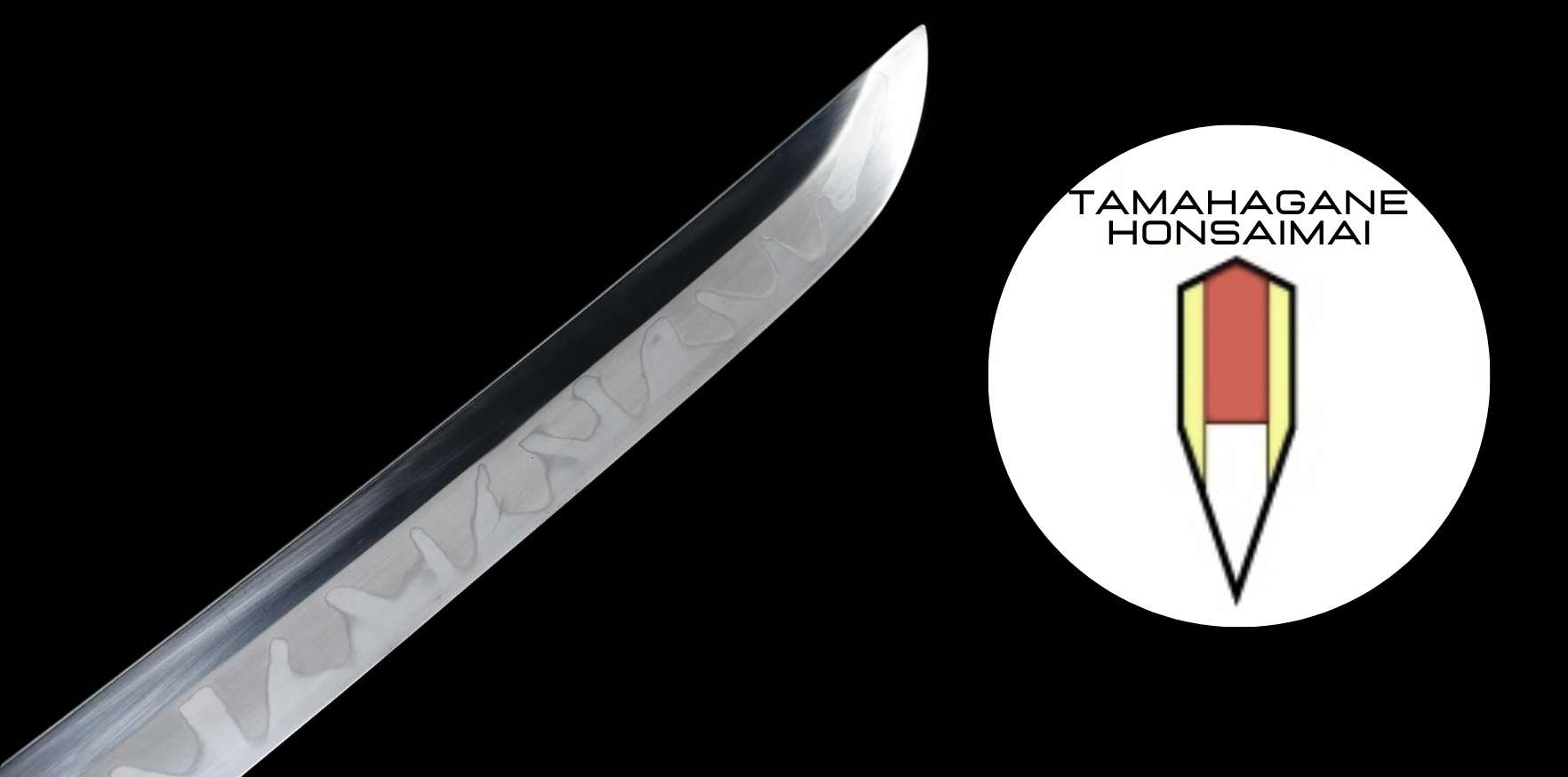

2.4 Tamahagane Steel

The pinnacle of traditional Japanese swordsmithing is the use of Tamahagane steel. This unique and rare steel is made from iron sand and charcoal in a clay Tatara furnace. It's characterized by its high carbon content and is often used in Shinken (real swords). Tamahagane is manually divided into high and low-carbon pieces, then combined in a careful lamination process that results in a blade of exceptional hardness and flexibility.

Key Points:

- Maru construction involves a single type of steel and is often used for economic and practice swords.

- Composite steel construction uses harder steel for the blade edge and softer steel for the spine, balancing sharpness and durability.

- Laminated construction involves layering and folding different types of steel, enhancing visual appeal and performance.

- Tamahagane, the pinnacle of traditional Japanese swordsmithing, results in a blade of exceptional hardness and flexibility.

3. Best Steel for a Katana

The choice of steel for a katana greatly depends on its intended use and the user's personal preferences. An authentic Nihonto, a modern martial arts practice sword, and a decorative piece will each have different requirements.

For practitioners of Iaido or Kenjutsu who require a practice sword, a blade made from high-quality Iaito steel or T10 steel can be a good choice. These types of steel offer a good balance of durability, sharpness, and affordability.

For a functional sword intended for cutting exercises (Tameshigiri), high carbon steel like 1060, 1095, or even the clay tempered and folded variety are often preferred. They maintain a sharp edge and are capable of withstanding high-stress cutting.

If you're in the market for a genuinely hand-crafted samurai sword or a high-caliber replica, Tamahagane steel continues to be the conventional preference. Renowned for its high carbon content, Tamahagane provides a blend of hardness and adaptability. Nevertheless, the rarity and intricate manufacturing process of Tamahagane steel make swords made from this material an exclusive and potentially costly acquisition.

On the other hand, for those looking to adorn their space with a katana purely for its aesthetics, stainless steel emerges as a practical and budget-friendly alternative. Despite its unsuitability for cutting exercises or martial arts training due to its brittle nature, stainless steel katanas require minimal upkeep. They can serve as an elegant complement to any collector's ensemble.

Key Points:

- The best steel for a katana depends on the sword's intended use and the user's preferences.

- High-quality Iaito steel or T10 steel can be suitable for martial arts practice swords.

- High carbon steel like 1060 or 1095, including the clay tempered and folded variants, are ideal for functional swords used in cutting exercises.

- Tamahagane steel is the traditional choice for authentic samurai swords and high-quality replicas, but can be very expensive.

- Stainless steel can be a suitable and economical choice for decorative swords.

4. Katana Steel Price Range

The cost of a katana can fluctuate considerably, primarily determined by the kind of steel utilized in its crafting. Generally speaking, the more labor and expertise the steel formation and sword-forging necessitate, the higher the katana's price tag.

<$100:

Katanas made from stainless steel are typically the least expensive, often falling under the $100 mark. These swords are mass-produced, mainly serving decorative functions. It's crucial to remember their fragile composition, making them unsuitable for martial arts practice or cutting drills.

$100 to $500:

Next in the pricing hierarchy are carbon steel katanas, crafted from materials such as 1045 or 1060 carbon steel. These functional blades range from approximately $100 to $500, frequently favored by martial arts novices for their balance of cost and utility.

$200 to $1000 :

Swords forged from superior carbon steels, including 1095 or T10, exhibit enhanced durability and superior edge retention. Frequently subject to clay tempering, these katanas often display stunning hamon lines. Prices for these katanas may range from $200 to well over $1,000, contingent upon factors such as craftsmanship quality, the swordsmith's renown, and additional unique elements.

$500 to $2000:

Folded steel katanas, embodying the traditional techniques of Japanese sword-making, command prices from $500 to more than $2,000. The complex folding process and resulting distinctive blade patterns heighten both their visual appeal and monetary worth.

+$2000:

Authentic Nihonto or Shinken katanas made from Tamahagane steel are the most expensive, typically starting around $3,000 and going well into the tens of thousands. The high price reflects the extensive labor, skill, and tradition involved in crafting these swords, as well as the rarity of authentic Tamahagane steel.

Key Points:

- Katana pricing is influenced by the type of steel used in its creation.

- Katanas made from stainless steel are typically the least expensive, with prices generally under $100.

- Katanas forged from carbon steel usually fall within the $100 to $500 price range.

- Katanas crafted from superior carbon steel could cost anywhere from $200 to over $1,000.

- Expect to pay from $500 to upwards of $2,000 for katanas made from folded steel.

- Authentic Nihonto or Shinken katanas made from Tamahagane steel are the most expensive, typically starting around $3,000.

Remember, a katana is more than just its steel. The skill of the swordsmith, the construction method, the fit and finish of the fittings, the balance of the blade, and the overall quality of the craftsmanship are all vital components in a great katana.