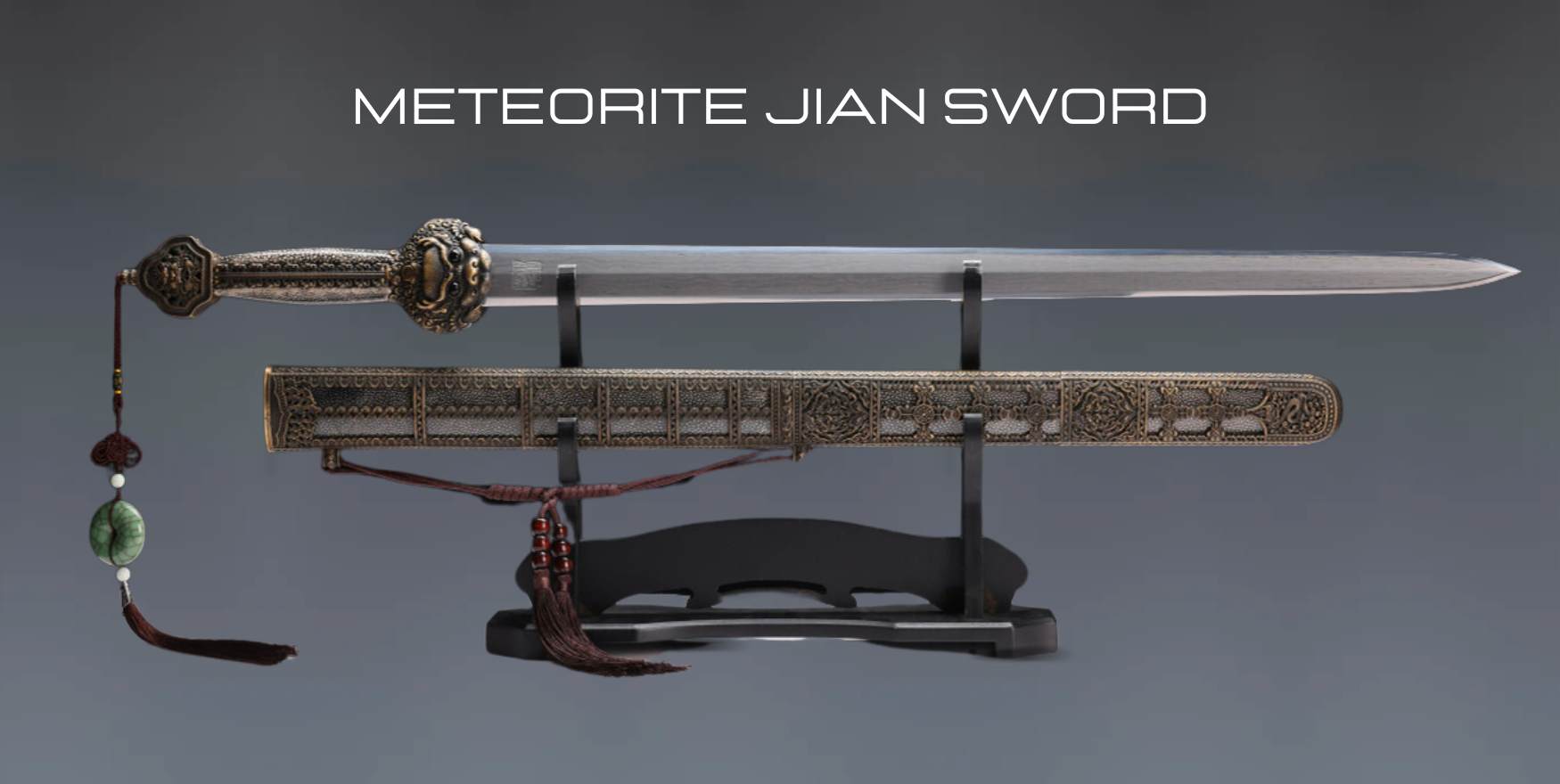

Meteorite sword

A meteorite sword is a type of blade forged from the iron found in meteorites that have fallen to Earth from space. This material, known as meteoric iron, is prized for its rarity and unique composition, which often includes a high percentage of nickel alongside the iron. The use of meteoric iron in sword making is a centuries-old practice that imbues these weapons with a sense of mystique and a connection to the cosmos.

Meteorite swords are not only valued for their exceptional material but also for the craftsmanship required to transform this cosmic iron into a functional and often beautifully patterned blade. The process involves smelting the meteoric iron, removing impurities, and then forging and tempering the metal into a sword. The result is a weapon that is as visually stunning as it is historically and culturally significant.

The allure of meteorite swords lies not only in their physical beauty and rarity but also in the symbolic connection between the heavens and the warrior spirit. These blades are considered to possess a unique energy and are often associated with power, endurance, and the pioneering spirit of their wielders. In both historical and modern contexts, meteorite swords are treasured as much for their aesthetic appeal and craftsmanship as for their extraordinary origin story, making them coveted items among collectors and enthusiasts of fine swords.

Characteristics of a Meteorite Sword

A meteorite sword, crafted from the rare and extraterrestrial material found in meteorites, is not only a weapon but also a piece of the cosmos itself. These swords carry distinctive characteristics that set them apart from other blades forged from more terrestrial materials. Here are some of the key features and qualities of a meteorite sword:

Material Composition

- Meteoric Iron: The primary material in a meteorite sword is meteoric iron, which includes iron-nickel alloys that are not commonly found on Earth. This gives the blade a unique molecular structure.

- High Nickel Content: The presence of nickel, often in higher quantities than found in earth-derived iron, contributes to a harder and potentially more corrosion-resistant blade.

Aesthetic Qualities

- Widmanstätten Patterns: When etched with acid, meteorite swords can reveal distinctive crystalline patterns known as Widmanstätten patterns, unique to meteoric iron.

- Unique Texture and Coloration: The inclusion of various minerals and the high nickel content can give the blade a unique texture and coloration, different from that of traditional steel swords.

Forging and Craftsmanship

- Complex Forging Process: The process of forging a sword from meteoric iron is complex and challenging, requiring specialized knowledge and techniques to handle the unique properties of the material.

- Custom Craftsmanship: Due to the rarity of the material and the difficulty of the forging process, meteorite swords are often custom-made, resulting in one-of-a-kind weapons.

Performance and Durability

- Hardness and Strength: The unique alloy of iron and nickel can offer superior hardness and strength, making meteorite swords highly durable.

- Cutting Efficiency: While the cutting efficiency of a meteorite sword can be exceptional, it largely depends on the forging process and the blade's geometry.

Rarity and Value

- Highly Prized: The rarity of meteoric iron, combined with the craftsmanship required to forge it into a blade, makes meteorite swords highly prized among collectors and enthusiasts.

- Significant Cost: The scarcity of the material, along with the specialized process required to craft it, results in meteorite swords being significantly more expensive than their terrestrial counterparts.

How is a Meteorite Sword Made

Making a sword from a meteorite is a complex process that combines traditional swordsmithing techniques with specialized knowledge to handle the unique properties of meteoritic iron. Here’s an overview of how a meteorite sword is made:

Selection of the Meteorite

- Identifying Suitable Meteorites: The first step involves selecting the right type of meteorite. Not all meteorites are suitable for sword making. The preferred types are iron meteorites, known for their high iron-nickel content.

- Authenticity and Quality: It's crucial to authenticate the meteorite and assess its quality. The presence of certain minerals and the overall composition can significantly affect the forging process and the final product.

Preparation of the Material

- Cleaning and Cutting: The meteorite is cleaned of any surface contaminants and cut into smaller pieces using high-precision tools to avoid wasting any material.

- Smelting: In some cases, the meteorite pieces may be smelted to purify the material, though this is a delicate process that risks losing some of the meteorite's unique characteristics.

Forging the Sword

- Heating and Hammering: The purified meteoritic iron is heated to high temperatures and hammered to shape. This process requires exceptional skill to maintain the integrity of the material while achieving the desired form of the blade.

- Folding and Welding: Similar to traditional Japanese sword-making techniques, the metal may be folded and welded multiple times. This process helps distribute the material's unique properties evenly throughout the blade.

Shaping and Sharpening

- Shaping the Blade: Once the basic shape is achieved, the blade is meticulously ground and sharpened. The goal is to balance the blade's sharpness with its structural integrity.

- Etching and Polishing: The blade can be etched with mild acids to reveal the meteorite's distinctive Widmanstätten patterns. After etching, the blade is polished to a fine finish.

Assembly and Finishing Touches

- Handle and Guard: The handle (tsuka) and guard (tsuba) are crafted and fitted to the blade. Materials for these components can vary widely, from traditional wood and leather to more exotic materials that complement the meteorite's origins.

- Final Assembly: The blade, handle, and guard are assembled with great care to ensure the sword is balanced and ready for use or display.

Challenges and Considerations

- Material Properties: Working with meteoritic iron presents unique challenges, such as its variable composition and potential for impurities that can affect forging.

- Skill and Experience: Crafting a sword from a meteorite requires not only traditional swordsmithing skills but also a deep understanding of the material's unique properties.

Is Meteorite a Good Material for a Sword

Using meteorite iron to forge a sword carries both a deep allure and significant challenges, making it a material that is more symbolic and ceremonial than practical for modern sword making. Below are key points evaluating meteorite as a material for swords:

Advantages

- Unique Composition: Meteorites, especially iron meteorites, have a unique composition, including high levels of nickel and rare elements like cobalt and gallium, which can impart distinct properties to the forged blade.

- Historical and Cultural Significance: Swords forged from meteorites carry a profound symbolic significance, connecting the weapon to the cosmos. This can make meteorite swords highly valued as ceremonial or display pieces.

- Aesthetic Appeal: The inclusion of meteoritic material can create unique patterns and textures on the blade, such as the Widmanstätten patterns, which are intricate and cannot be replicated by terrestrial means.

Disadvantages

- Variable Quality: The composition of meteorites can vary widely, making it difficult to predict the performance and workability of the material. Some meteorites may contain high levels of impurities or structures that are not ideal for forging into a blade.

- Difficulty in Working: Meteorite iron can be challenging to work with, requiring specialized techniques to forge, shape, and temper the material without losing its unique characteristics or compromising the integrity of the blade.

- Cost and Rarity: Meteorites are rare and can be expensive to acquire, particularly larger specimens suitable for sword making. This rarity and cost make meteorite swords impractical for widespread use.

- Durability Concerns: While meteorite iron can be hard and durable, the presence of certain elements and the lack of control over the alloy's specific composition can result in blades that are more brittle or prone to corrosion compared to those made from modern steel alloys designed for sword making.

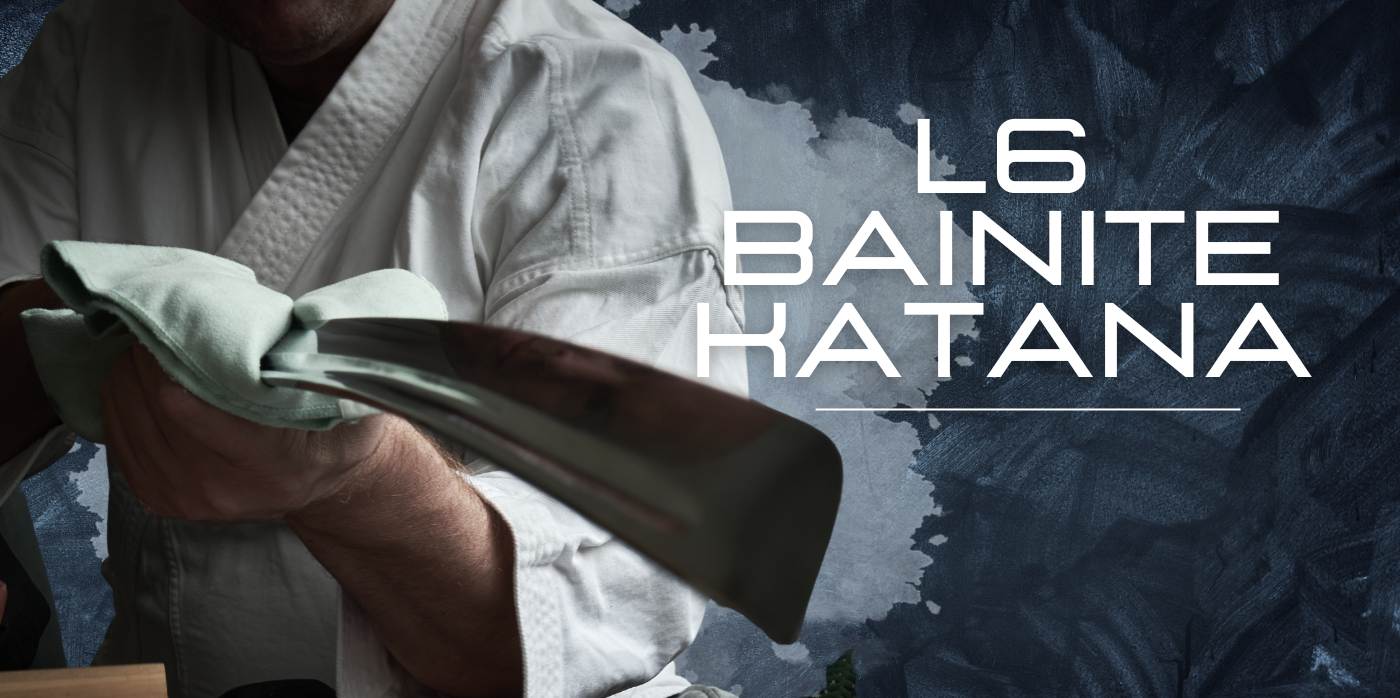

Katana Made From Meteorite

The Meteorite Katana stands as a celestial marvel in the world of traditional Japanese swords. This unique type of katana, forged from meteorite iron, embodies not just the unmatched skill of the Japanese swordsmiths, but also the cosmic energy of the universe. The concept of using meteoritic iron to craft a blade infuses these katanas with a sense of mystique and unparalleled value, making meteorite katanas a sought-after piece for collectors and practitioners alike.

The Forging Process of a Meteorite Katana

Crafting a katana from a meteorite is an art that marries ancient sword-making techniques with the cosmic origins of meteoritic iron. The process begins with the careful selection of meteorite material, which is known for its high nickel content and distinctive Widmanstätten patterns. These characteristics not only contribute to the meteorite katana's aesthetic appeal but also enhance its structural integrity.

The forging of a meteorite blade requires a swordsmith skilled in traditional methods, as the material demands precise heating, hammering, and folding techniques. This painstaking process ensures that the sword blade maintains its legendary sharpness while embodying the cosmic essence of the meteorite itself.

Is meteorite katana best than regular katana

Comparing a meteorite katana to a regular katana involves considering factors beyond just materials, such as craftsmanship, purpose, and the symbolism behind the sword. Here's a breakdown of how they might compare:

Material and Craftsmanship

- Regular Katana: Crafted from high-quality steel, such as tamahagane, and through a process that involves folding and differential hardening, regular samurai swords are designed for balance, sharpness, and durability. The expertise and traditions behind their forging ensure they are not only effective weapons but also works of art.

- Meteorite Katana: A katana forged from meteorite iron can be exceptional due to the rarity and cosmic origin of the material. The iron in meteorites, rich in nickel and other metals, could potentially add unique characteristics to the blade. However, the practical benefits in terms of blade performance compared to high-quality steel are more symbolic than functional.

Durability and Performance

- Regular Katana: These are proven in combat and practice, optimized for cutting efficiency, durability, and balance. The meticulous process of creating a traditional katana ensures a blade that can withstand rigorous use while maintaining its edge.

- Meteorite Katana: While meteorite iron can be forged into a blade, its performance as a weapon is more uncertain. The material's consistency, potential for impurities, and the novelty of using such a metal mean it might not match the reliability and performance of a traditional katana. Its durability and sharpness could be compromised by the material's natural characteristics.